Inspection/Measurement

JFE-TEC's Surface-distortion Measurement Device SurfTRiDY

Overview of the JFE-TEC's Surface-distortion Measurement Device SurfTRiDY

The surface-distortion measurement device SurfTRiDY measures the distortion distribution on panels based on a unique stripe-pattern image analysis method (SurfTRiDY method) and indicates the measurement results.

The device can store measurement results as electronic files, which allows you to compare the amounts of the surface distortion of samples with each other manufactured at different times and/or in different places based on the same measures.

The SurfTRiDY helps you establish surface distortion traceability in the fields of product development, production control, and quality assurance in the areas where surface distortion is an important quality consideration, such as vehicles, plastics, glass, films, construction materials, and paintings.

How the SurfTRiDY Makes Measurements

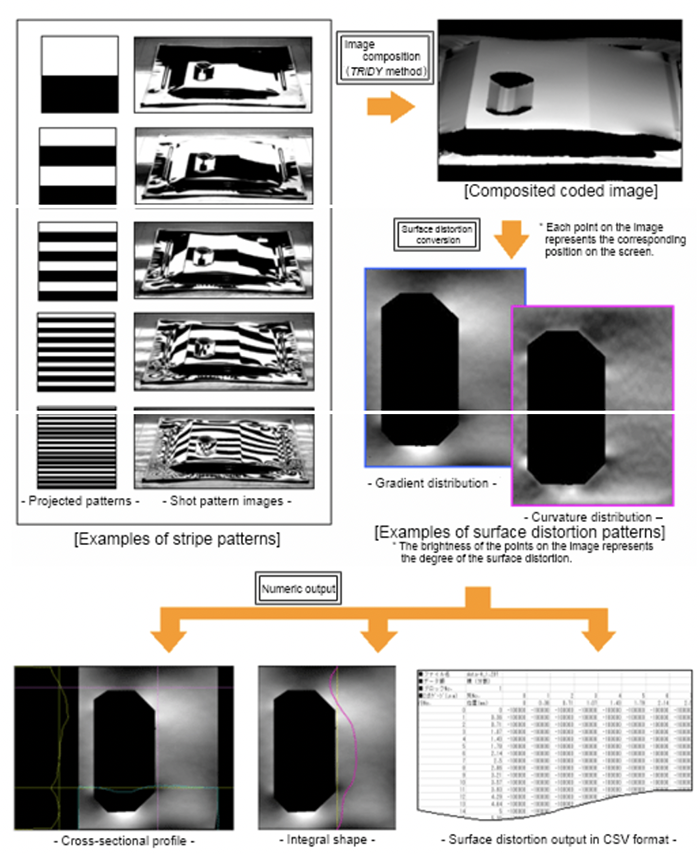

1) Measurement Principle (Fig. 1)

When you observe the on-screen mirror image of stripes reflected on the surface of a specular object, the stripes look distorted according to the distortion of the surface (zebra pattern observation).

The distortion degree depends on the gradient of the surfaces. The SurfTRiDY measures distortion patterns by determining the coordinates of the on-screen points corresponding to all points on the surface of the object to quantify the degree of distortion of the stripes.

2) Measuring Method (Fig. 2)

On a screen, the system projects "stripe patterns with different cycles" and then "moving multi-slit patterns" to observe the mirror images reflected on the surface of the observation object through a TV camera.

The system analyzes these images based on the SurfTRiDY method to convert them into gradient patterns.

After that, it differentiates them to determine the curvature patterns.

(*)

TRiDY method: This is the stripe-pattern image analysis method used in the three-dimensional curved-surface shape measurement device SurfTRiDY from JFE Techno-Research Corporation. The SurfTRiDY projects "stripe patterns with different cycles" and then "moving multi-slit patterns" directly onto the surface of an observation object such as a human body.

Then, using a TV camera, it shoots the distortion of the projected patterns ascribable to the unevenness of the object and processes the obtained images to determine the shape.

It provides high-speed, reliable measurements using the image encoding method (one of the space encoding methods) to process the multi-slit patterns and offers high-precision, absolute-value measurements by combining two types of projection patterns (it uses the SurfTRiDY method).

The SurfTRiDY is different in that it uses an optical measurement system that projects the patterns on a screen and observes the mirror image of the patterns projected on the screen instead of projecting the patterns directly on the observation object. However, it uses the same SurfTRiDY method to process the obtained images.

3) Applications

Observation, Recording, Evaluation, and Inspection of the Surface Distortion of Specular and Semi-Specular Objects

- Examples of measurement objects - Press panels, coated panels, sheet/plate glass, plastics, films, and more

(*)The SurfTRiDY may be able to measure even objects with dull surfaces, if you apply a coating of oil to their surfaces to make them specular.

Description of the Products

The SurfTRiDY kit is a system consisting of only the basic components (a TV camera, projector, and PC) and software. It is mainly designed for use in experiments and development activities.

- With a combination of a desired camera and projector according to the size and/or posture of the object, this kit can be used to observe the surface distortion patterns of objects (you are kindly requested to have a screen and measurement rack ready).

- The kit provides a base system that JFE-TEC customizes the equipment according to your intended use.

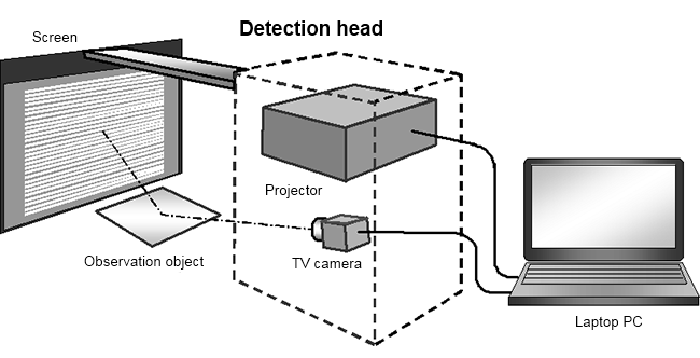

The SurfTRiDY mobile is a compact combination of the measurement-head components (a TV camera, projector, and screen) in one unit. It is mainly designed to be used for the on-site measurement. - With combined use of the optional arm and rack, the product can be easily brought near measurement observation objects.

- The visual field is fixed at 120 mm and the detection head weighs approximately 5 kg.

1) System Configuration

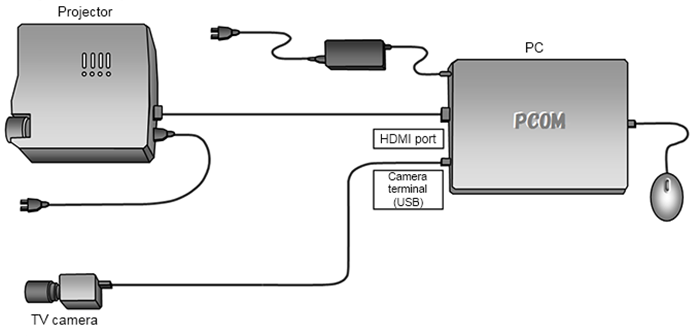

SurfTRiDY kit (Fig. 3)

Hardware

- A laptop PC with a set of accessories

- A TV camera with a set of accessories

- A projector with a set of accessories

- A set of cables (for connection and power supply)

(*)Note that the components shown above may differ from the actual product in appearance.

(Note 1)To guarantee correct system operation, we will select appropriate hardware components, incorporate them into the system, and make adjustments before delivering the system to our client.

(Note 2)The hardware models are subject to change without prior notice.

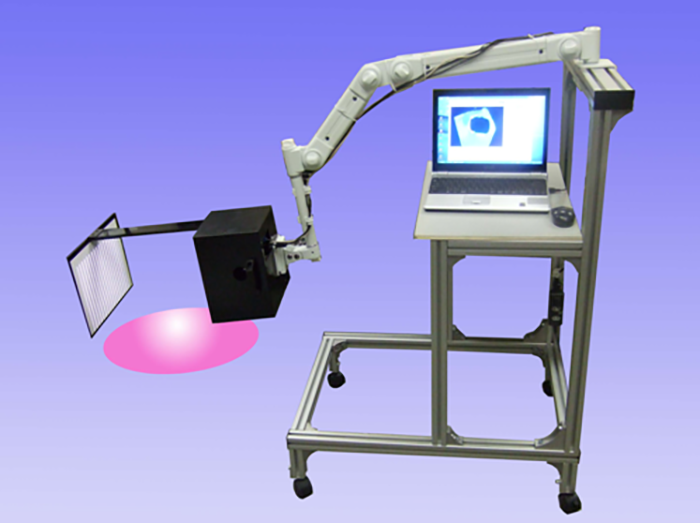

SurfTRiDY mobile (Figs. 4 and 5)

Hardware

- A detection head with a set of accessories

- A laptop PC with a set of accessories

- A set of cables (for connection and power supply)

*Specifications of the detection head

- Measurement visual-field width: 120 mm

- Dimensions of the detection head: 340 (W) x 300 (H) x 550 (L) (including the screen dimensions)

- Weight of the detection head: approximately 5 kg

(*)The appearance and weight of the detection head are subject to change without prior notice.

(*)The arm and rack in the photo are optional. The appearance is subject to change without prior notice.

Software

- Measurement function: Projects coded patterns on the screen to capture the zebra pattern on the surface of the observation object.

- Image composition function: Performs computation on the screen-position coded image based on the coded zebra pattern.

- Surface-distortion conversion function: Converts the screen-position coded image to a surface-distortion image to indicate and output the resulting image.

- CG display function: Graphically displays the surface distortion pattern.

- Save-in-CSV function: Saves surface-distortion patterns as CSV files.

(Note)The bundled software is subject to change without prior notice.

2) Performance and Features

| High-speed measurement: | Shooting time of 3 to 10 seconds and surface-distortion computation time of approximately 2 seconds |

|---|---|

| High-sensitivity measurement: | Detects changes in the gradient (gradient of 1 mm per 1 m) on a 1-mrad surface. |

| Quantitative pattern measurement: | Digitalizes distortion distribution on the entire surface of the observation object. |

| Low environmental/object dependency: | Capable of measuring even black specular objects without requiring the room to be pitch dark. |

| Easy operation: | A single unit of PC allows all operations from measurement to data indication and storage. |

| Rich indication/output capability: | Color-map and CG bird's eye views and data saving in CSV format (editable with Excel) |

| Compact and lightweight: | Can be stored in a case on wheels, and then carried to the site and assembled by one person for measurement(SurfTRiDY kit) |