Disassembly Investigation of Batteries and Capacitors,

Investigation for Deterioration and Defect, and Structural Analysis

Disassembly Investigation of Batteries/Capacitors

In-page menu

JFE-TEC provides disassembly investigation services for investigation of parts of commercial batteries/cells and investigation of the causes of swelling, smoke, fire, etc. in failed

batteries.

JFE-TEC also provides investigation of cause and mechanism of deterioration of batteries by conducting investigation of battery materials after long term deterioration tests.

We also provide investigation of battery materials of commercially available batteries/cells, and disassembly investigation to study cause of failure batteries suc

0h as swelling

or smoking/fire, etc.

At JFE-TEC, it is possible to perform the total disassembly process of batteries and capacitors under an ultra-low dew point environment by using an Ar glove

box and dry room.

We also provide integrated services including chemical analysis and physical analysis under atmospheric isolation.

Types of Batteries Available for Disassembly

JFE-TEC can perform disassembly investigations of a wide range of cells, batteries, and capacitors.

Please consult with us for disassembly investigation of newly-developed products.

| Materials | Forms | Types of Batteries |

|---|---|---|

|

|

|

- LIB : Li-ion Batteries

EDLC : Electric Double Layer Capacitors

LIC : Li-ion Capacitors

-

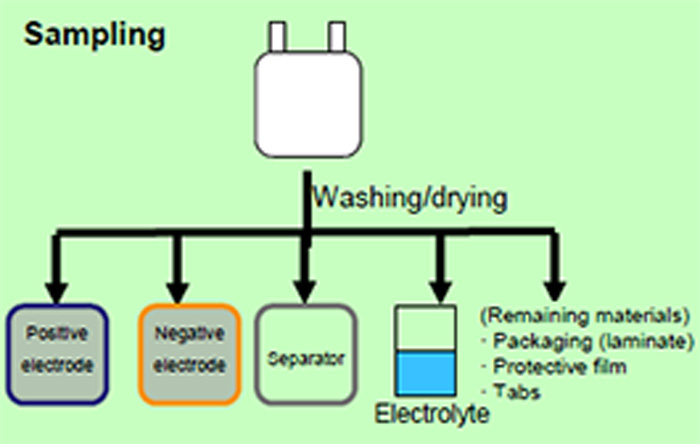

Flow of Battery Disassembly Investigation -

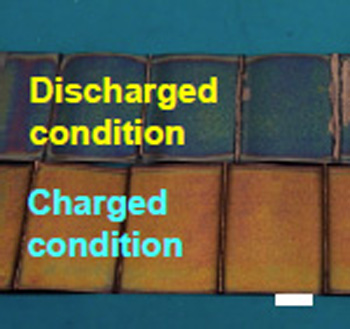

Graphite negative electrodes sampled from disassembled batteries

Flow of Battery Disassembly Investigation

Before disassembly, the internal structure is investigated to minimize damage to the electrodes, separators, and other structural parts and to enable safe

disassembly.

Also, witnessing by the client is also possible.

- Standard example of disassembly procedures -

- Charge-discharge characteristics test

(available on request) - Investigation of internal structure by X-ray

fluoroscopy/X-ray CT

(to ensure safety and minimize damage to parts) - Battery disassembly

(performed in Ar glove box/dry room) - Sampling of battery structural parts

(all parts, including packaging materials) - Chemical and structure analysis of battery

component materials

Analysis methods for component materials of batteries and capacitors

| Material | Purpose | Method | |

|---|---|---|---|

| Electrode |

Electrode/active material (incl. conductive aid) |

Identification of crystal structure and components of electrode |

X-ray diffraction |

| Elemental composition analysis | ICP | ||

| Cross-section structure analysis | FIB, cross-section Ar milling | ||

| Surface state analysis | XPS | ||

|

Negative electrode/active material (incl. conductive aid) |

Graphite content of graphite negative electrode Crystalline orientation, crystal size |

X-ray diffraction | |

| Cross-section structure analysis | FIB-SEM, CP-SEM | ||

| Surface state analysis | XPS | ||

| Binder | Analysis of components of binder and thickener | FT-IR Thermal decomposition- GC-MS |

|

| Tab lead | Ultrasonic welding state investigation | Cross sectional SEM | |

| Separator | Components | Microscopic FT-IR | |

| Layer composition | SEM, microscopic Raman | ||

| Electrolyte solution | Solvent | Moisture content analysis of main component, impurity and modified product | GC, GC-MS Karl Fischer method |

| Electrolyte | Component analysis | LC-MS, ICP | |

| Additive | Component analysis | FT-IR, GC-MS | |

| Cladding | |||