Study and Analysis of a Root Cause of Failure

in Resin Composite Materials

Evaluation of Lifespan of Rubbers and Plastics

Using the accelerated aging tests at elevated temperature JFE-TEC can provide the analysis service within a few days to a few weeks for estimating the lifespan of organic materials such as rubbers and plastics.

Accelerated Aging Test and Prediction of the Lifespan

- If durability, that is, the lifespan of rubbers and plastic products is determined in the real usage conditions, the test will take a few years to hundreds of year and is not practical.

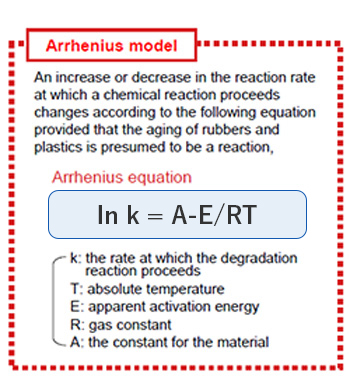

- JFE-TEC uses the accelerated aging tests at elevated temperature and uses the Arrhenius equation for quantitatively predicting the lifespan.

(The endurance index and the lifespan prediction criteria have to be set depending on the product quality required. Please refer to the following example on these criteria).

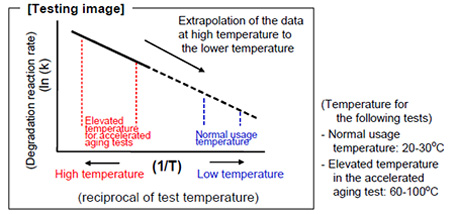

The way to predict the lifespan of the products in the normal

usage temperature using the Arrhenius model

Evaluation Example of Rubber Sealants

Example of the Degradation Criteria and Lifespan Prediction

In prediction of the lifespan of the sealants the curing reaction of rubber is used for a model of the deterioration of the sealants.

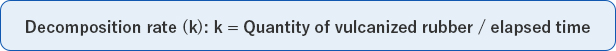

(1) Degradation of the material is accelerated at high temperature and the hardness of rubber is determined.

-

Photo 1 A durometer for determining the hardness of rubber compounds Measurement equipment: Micro durometer MD-1 capa Hardness: Shore Duromter A scales of hardness Indication range: 0 point - 100 points (The higher the value the rubber is harder). -

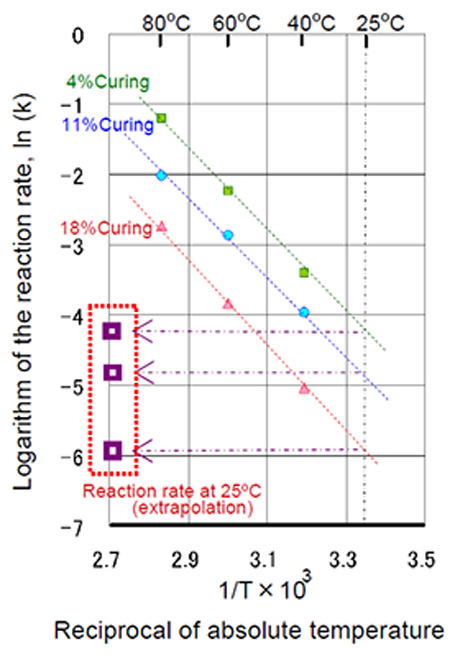

(2) The curing reaction at the same cure content is used for the Arrhenius plot.

Figure 1 Arrhenius plots of curing of rubber at the same cure content -

(3) The value of ln (k) extrapolated in the Arrhenius plot in

Figure 1 is presumed to be a change of the hardness of rubber used at 25℃ with time.

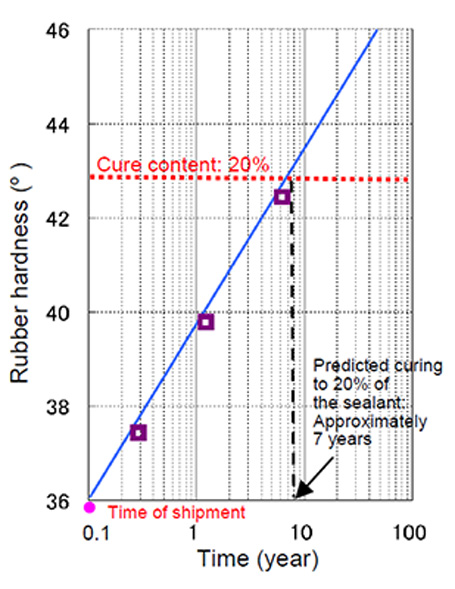

Figure 2 A change of rubber hardness at 25℃ with time The lifespan of the sealant studied is predicted around 7 years

provided its lifespan is the time when the cure content reaches 20%.