Analysis and Investigation of Electronic Components/Electronic Devices

Examples of Defects of IC/LSI Products

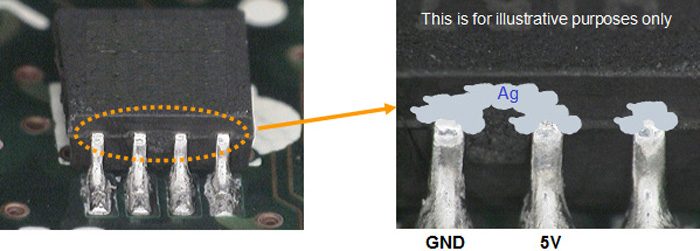

Ion migration between terminals [Short-circuit failure of IC products]

-

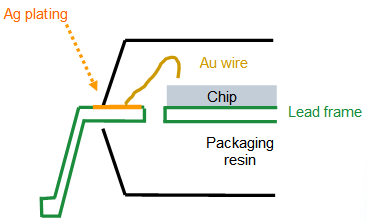

Silver(Ag) is easily corroded by sulfur compound gas*, etc. Therefore, IC parts are packaged so that the Ag-plated portion is not exposed to the outside of the package.

If Ag plated portion of the lead frame is exposed to the outside of the packaging resin, Ag corrodes and Ag causes ion migration (in the case where there is a potential difference between terminals), resulting in a short circuit between terminals. In the environment with a higher humidity, corrosion can be accelerated.

*Trace amount of sulfur compound gas may be present depending on the region and operating environment.

-

Illustration of exposed Ag-plated portion to the outside of the package

Chip/packaging resin peeling [Open failure of LSI product]

-

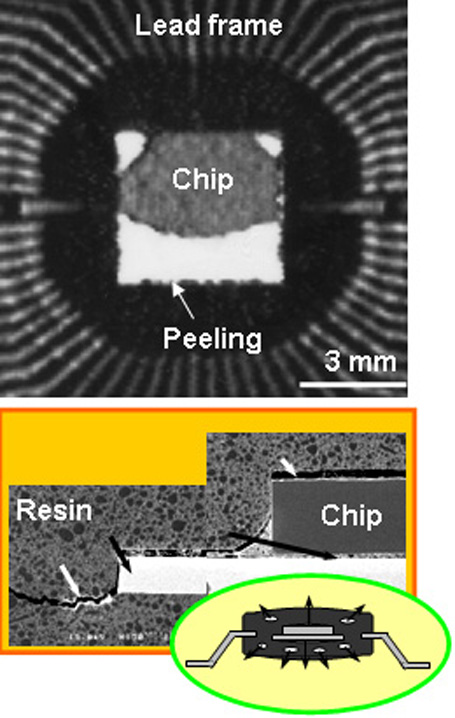

The failure occurred on the LSI product after mounting on the printed circuit board.

As a result of checking for interfacial peeling between the chip and the resin using the scanning acoustic microscope/tomograph (SAM/SAT), a peeling was found at the chip and the packaging resin interface .

It is presumed that since the packaging resin had absorbed moisture, a steam explosion occurred due to the sudden heating during reflow, leading to a break of the wire.

-

* Interface between chip and the packaging resin interface

Gold(Au) wire failure [Open failure of LSI product]

-

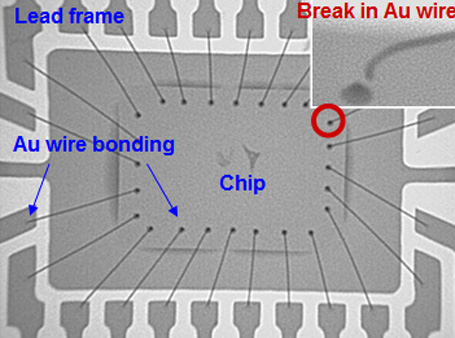

During the product receiving inspection, the failure was found.

The inside Au wire was observed by the transmission X-ray observation (microfocused X-ray). As a result, a break was found at the neck portion of the 1st bonding.

Break in Au wire may be caused by popcorn phenomenon during reflow (resin/chip interfacial peeling), bonding failure, etc.

-

Transmission X-ray observation of IC Chip

Overcurrent destruction [Open failure of LSI product]

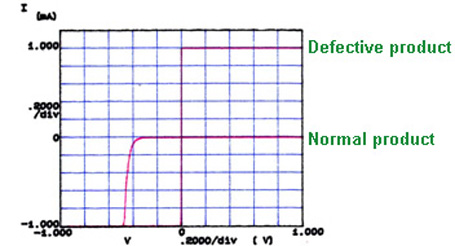

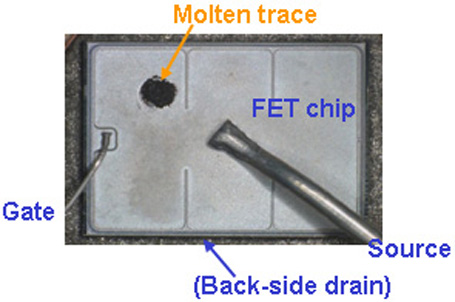

The failure of FET was found at the market.

As a result of the measurement of I-V property, it was found that all portions between the gate, the source and the drain were short-circuited. The resin was opened and the internal observation was conducted. As a result, a molten trace was found on the FET chip.

-

Voltage-current characteristics

between the drain and the source -

Corrosion of Internal Aluminum Wiring [Case Study of Failure Analysis of IC, Transistor]

The figures below show a case study in which operation caused unstable behavior in a certain electronic board, and the related IC component was investigated to clarify the cause.

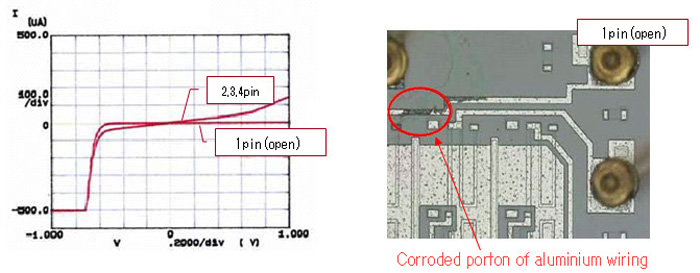

The graph at the left shows the results of measurements of the electrical characteristics of several terminal pins, which revealed that 1 pin was open. Based on this, it was estimated that an abnormality had occurred in the wiring or connection of 1 pin.

The mold resin of the IC product was dissolved, and the chip surface was observed. The result is shown in the photo at the right. Discoloration of the aluminum wiring of 1 pin in the IC chip can be observed in the part enclosed in the red circle.

It is known that aluminum wiring (Al wiring) generally displays this kind of appearance when it is oxidized or undergoes hydration as a result of corrosion. Thus, it can be understood that malfunction occurred as a result of progressively higher resistance of the aluminum wiring due to corrosion.