Battery and Capacitor Prototyping

Examples of Battery and Capacitor Prototyping Evaluation

The following shows examples of prototyping evaluation of a general lithium-ion secondary battery and a capacitor.

JFE-TEC conducts prototyping evaluation according to the request of the customer. Please feel free to contact us for specifications, etc. (type, dimensions, capacity, etc.).

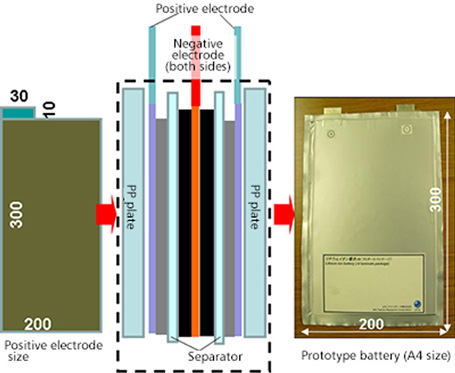

Example of Battery Prototyping Evaluation - Evaluation of A4 Size (Capacity: 1 Ah) Battery Prototyping -

-

- Electrode material ... a LiCoO2-based positive electrode material prototyped using a continuous coating machine and a natural graphite-based negative electrode material (coating width: 200 mm × C)

- Battery design ... combining material of negative electrode on both sides and two positive electrodes (185 × 280 mm)

Cross section of the cell -

-

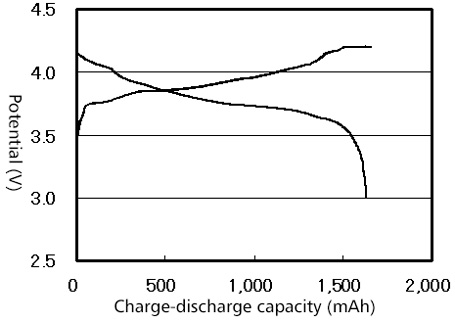

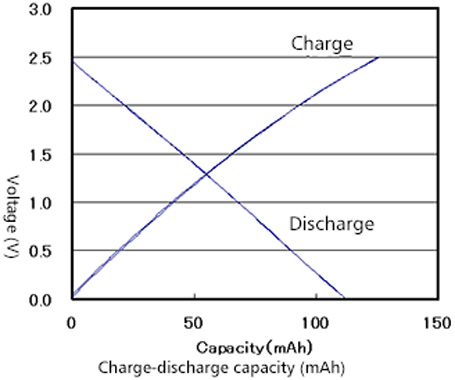

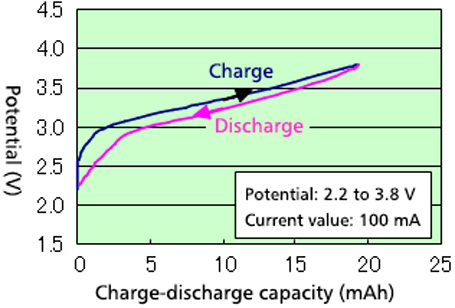

Figure: Initial charge-discharge curve -

An initial capacity of approx. 1,700 mAh is achieved with two electrodes of 200 × 300 mm in size.

Related link

-

Electric Double-Layer Capacitor

Outline of Electric Double-Layer Capacitors (EDLC)

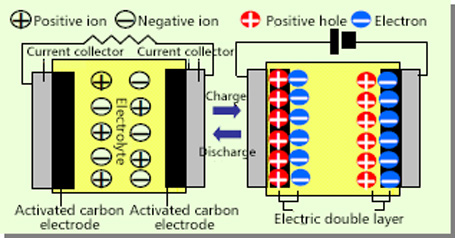

An electric double-layer capacitor stores charge by using a phenomenon in which positive charge and negative charge are arranged on the interface of a conductor immersed in an electrolyte.

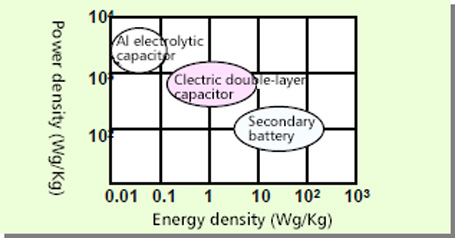

Although the density of the stored energy is small, the power density is high, and it is therefore capable of rapidly charging and discharging electricity (Fig. 2). EDLC is expected to serve as a backup power supply or an auxiliary power supply for starting/operating the motor of automobile or electric equipment.

From capacitor prototyping, characteristic evaluation and analysis of the capacitor can be achieved.

-

Fig. 1: Principle of the electric double-layer capacitor -

Fig. 2: Energy density and power density

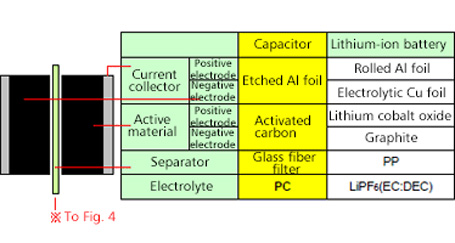

Configuration of an electric double-layer capacitor (EDLC)

-

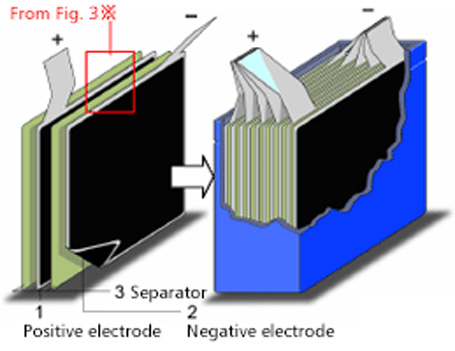

Fig. 3: Example of capacitor configuration (cross section) -

Fig. 4: Laminate cell

Example of Electric Double-Layer Capacitor (EDLC) Prototyping Evaluation

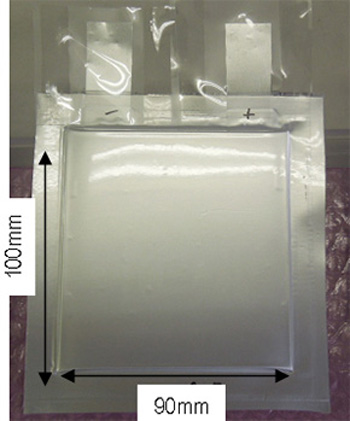

An electric double-layer capacitor (EDLC) cell with an initial electrostatic capacity of 166 F is prototyped.

-

-

Electrode (activated carbon)

Deposit: 5mg/cm2

Size: 96 × 84 mm Five -

Negative electrode (activated carbon)

Deposit: 5mg/cm2

Size:96 × 84 mm Six

-

Electrode (activated carbon)

-

Appearance of the EDLC cell -

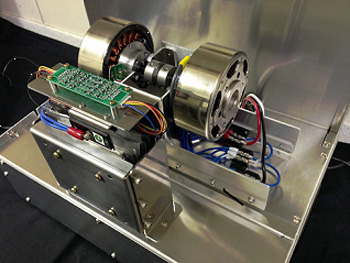

Case example of a module equipped with an EDLC prototyped by our company

(joint prototyping with the Industrial Research Institute of Shizuoka Prefecture)

Initial Electrostatic Capacity Evaluation

-

Initial electrostatic

capacity166F Internal resistance 3.4mΩ -

Example of initial electrostatic capacity evaluation -

- Electrolyte: 1M (C2H5)4NBF4 /PC

- Temperature: room temperature

Lithium-ion Capacitor

Outline of Lithium-Ion Capacitors (LIC)

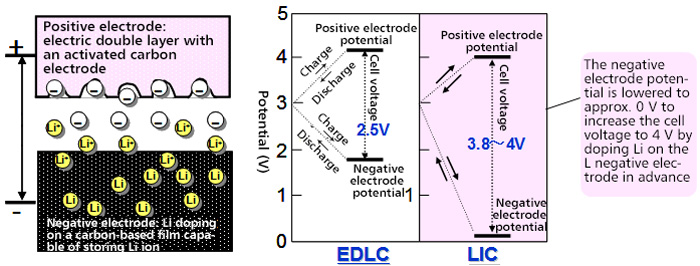

In a lithium-ion capacitor (LIC), an activated carbon electrode is used as the positive electrode as with an electric double-layer capacitor (EDLC), and a carbon-based electrode as the negative electrode as with a lithium-ion battery.

LIC is a next-generation electric storage device that achieves both a high operating voltage (high power) and high energy density by using Li pre-doped on the negative electrode.

Structure and an Example of Prototyping Evaluation of a Lithium-Ion Capacitor (LIC)

Structure of a lithium-ion capacitor (LIC)

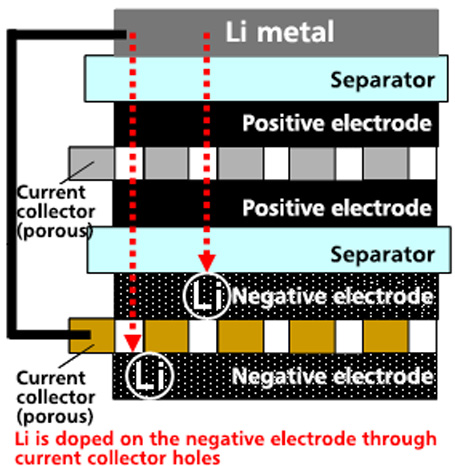

In LIC, Li metal is short-circuited to the negative electrode or Li is doped in the negative electrode by constant current load.

Therefore, in some laminate cells, porous current collectors as shown in Fig. 2 are used.

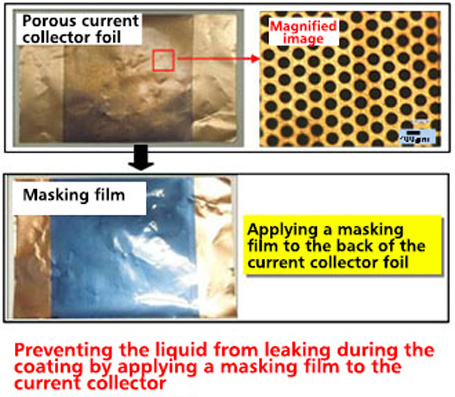

In such cases, it is necessary to take a measure to prevent the liquid from leaking to the back during electrode film coating.

Our company performs electrode film formation on porous current collectors by using a masking film (Fig. 3).

-

Cell structure of LIC -

Method for prototyping an electrode for LIC (case example)

An environment for prototyping lithium-ion capacitor (LIC) and an example of its evaluation

Since metallic lithium is to be handled, a working environment with a low dew point is essential.

Our company has installed an integrated cell prototyping facility in a dry room in order to provide our customers with an LIC prototyping environment.

-

Example of initial characteristic evaluation -

Appearance of the prototyped LIC cell